Careers

We offer the flexibility, training, tools, and technology that can launch and propel your career! We look for team players with initiative, creativity, and a passion for winning.

See Open Positions6 Reasons to work at ATC

Community Involvement

We believe in supporting the communities where we live and work by providing investments that support and promote the welfare of others.

Life & Culture

Our culture is trust-based and encourages collaboration, entrepreneurialism and innovation, which drives our performance and creates a rewarding workplace.

Achievement

We recognize and reward employees for their contributions, dedication, and commitment to the achievement of American Textile’s business goals.

Multiple Locations

ATC employees work in Pennsylvania, Georgia, Texas, Utah, El Salvador and China. Look at job openings for an opportunity near you.

Benefits & Wellness

We offer a comprehensive benefits package including health insurance, 401k with company match, tuition assistance, and more.

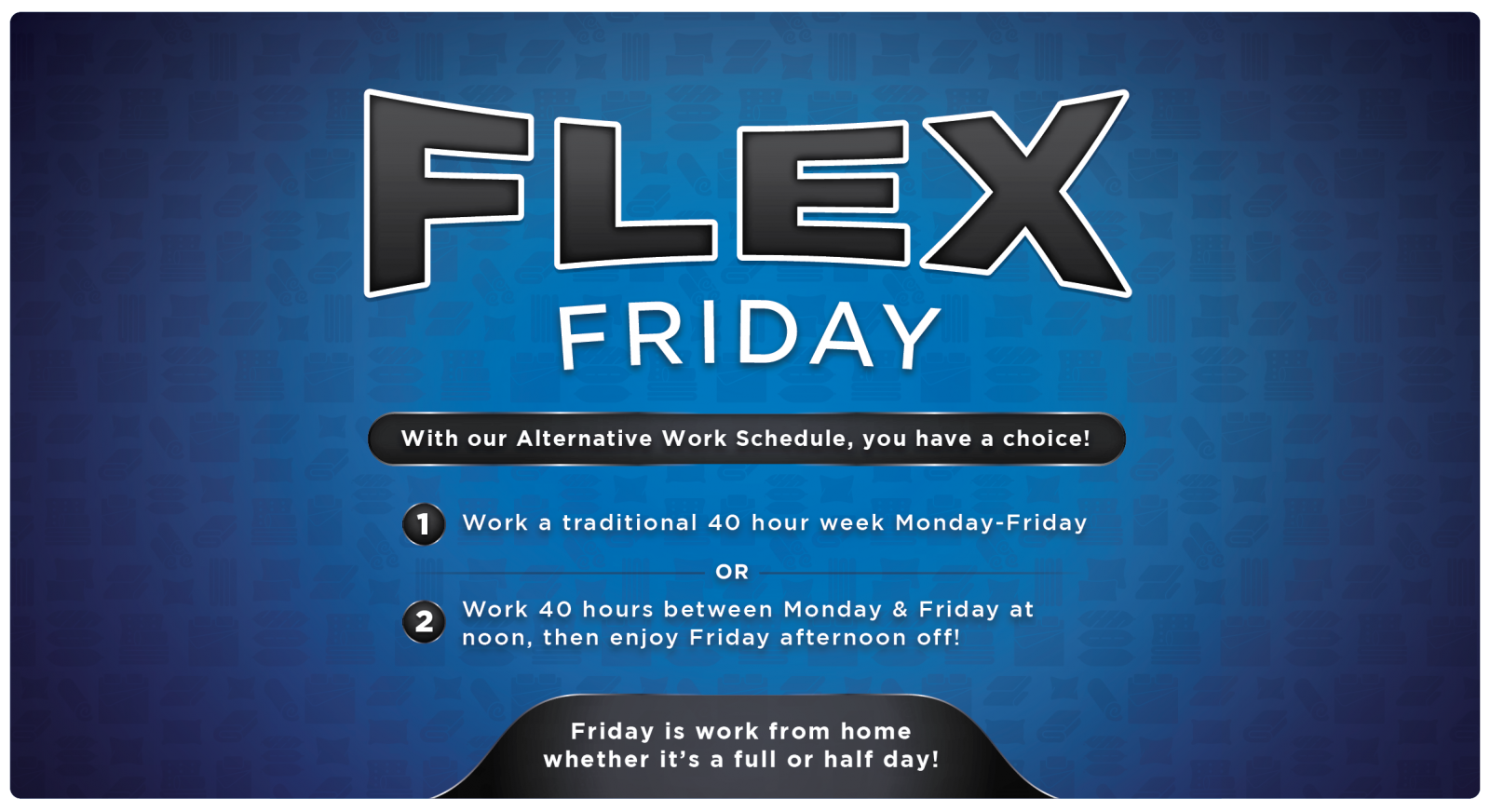

Work-Life Balance

We believe in a healthy work-life balance. While we work hard, we also want you to have room for family, friends, and, of course, yourself. At ATC, we believe it’s important to pursue our passions outside of the office.

Hear it from them

Open Positions

Tell us how we can help.

All the latest from ATC.